Establishment of KODEN production method

Basic spirit of production innovation activities 10 articles

| 1.Discard the stereotype of how to make it 2.Consider how to do better than the explanation of why you can not. 3.Do not make excuses. First deny the current situation. 4.I will do good things at once. I stop making bad things right away. 5.Do not ask for perfection. Even 50 points are good, so you can proceed anyway. 6.Please fix the moment right away! 7.If you do not mind, you do not have wisdom. 8.Pursue the root cause - why after 5 times how to improve!  9.Ten wisdom more than one inspiration! 10.Improvement is infinite. |

The word is "Have fun working and make money with 4S strategy!"

A thorough 5S

Especially organize, make visible by organizing, aim for space 1/2

Space 1/2 is not simply to make space, but to make waste such as making too much, buying too much, making it quickly!

Slogan

Example Drawing management and visualization of schedule

The layout according to the calendar makes it easy to see if there are any plans and confirms the drawings.

Example Improvement of material storage (visualization of schedule)

It is easy to understand the classification of the day and the next day, and it is possible to correspond to the increase and decrease of the quantity by making it a slide type

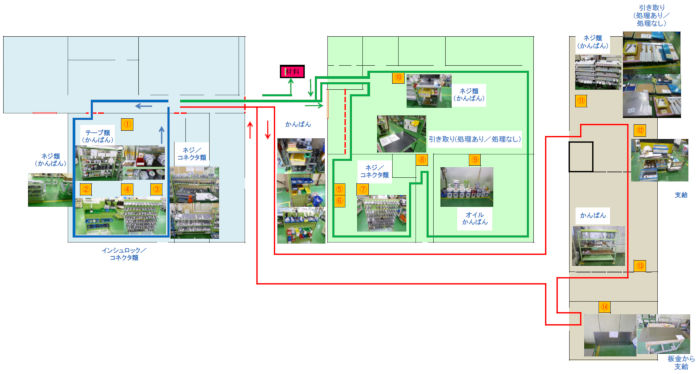

Example Implementation of Mizusumashi

By performing Mizusumashi, the number of man-hours required for members of each department to make arrangements and confirmations is greatly reduced.

Insulation lock and tie mount are subdivided so that multiple members can use it at the same time.

Realization of visualization of replenishment timing

Example JIG / tool 2S

Reduction of searching and visualization of tools in use

Example Painting tool 2S

Reduction of searching and visualization of tools in use

Example Sheet metal material storage 2S

Continuing from 2017 and 2018, reducing space by devising methods for storing sheet metal materials

Since the material itself is large, it has a great effect by devising the placement

Example material storage space 2S (1/2 space)

Material storage space with a working space secured by 2S

Example Warehouse 2S (1/2 space)

Warehouse where working space is secured by 2S

The yellow line drawn on the floor is the arrangement position before improvement

Example Welding work improvement

Prepare a workbench to improve the welding posture and improve work efficiency

Past 5S examples

4S strategy

| <<Save>> 1.Let's eliminate the waste of reworking. 2.Let's eliminate waste of scraps and improve yield. 3.Lose waste of expenses. 4.Let's stop wasteful capital investment. |

| <<Stock>> 1.Do not make too much, let's not waste too much. 2.Let's not waste inventory and work in progress. 3.Lost work unbalance, waste. 4.Lose waste of "waiting for hand" due to machine failure. |

Japan's top factory

Japan's top factory

| <<Space>> 1.Lose waste of layout. 2.Let's get rid of unfinished waste. 3.Let's avoid waste space of unnecessary items and idle facilities. |

| <<Strength>> 1.Let's realize just-in-time strong production. 2.Let's not wasteful waiting. 3.Let's not waste the operation. 4.Lose waste of transportation. 5.Lose waste of processing method. 6.Let's not waste the reserve. |

Three principles of production innovation activities

| 1.Is the employee functioning? 2.Are employees participating in management? 3.Is information sharing being done? |

STEP of production innovation

Starting STEP - 0, we are implementing 2S thoroughly.

| STEP-0 Organize and Organize (2S) Organize : Separate what you do not need and what you are. Tidy : Anyone can take out something immediately. |

| STEP-1 Create a rough flow · 1 piece making, 1 piece sinking · Improved from large movements to small movements · Store creation, gimmicks, shelf making · Layout change (margin reduction) · Logistics design |

| STEP-2 Create a strong flow · Improvement of setup change · Multipurpose engineering · Inlining · Review of internal and external categories · Review of operated flights (route flights) |

| STEP-3 Create an accurate flow · Improvement of packaging (Smaller: reduced to box) · Thorough leveling · Improve accuracy of standard work (to rhythmical and smooth movement) · Maintenance mechanism of abnormality manifestation |

| STEP-4 Creating a managed flow · Manualization of KANBAN operation (also expanded to other mechanisms) · Creating mechanisms for preventive management in QCD · Enhanced facility preventive maintenance · Education training manualization · Establishment of 5S |

Production request, estimate

TEL: 048-541-1521

Business hours: Mon-Fri 8: 00-17: 00

We accept consultations on the introduction of automated machines, equipment, and equipment for automation, labor saving, and unmanned operation of factories and laboratories. In Japan, we have a wide range of delivery records from Aomori to Kyushu, mainly in the Kanto region (Saitama, Ibaraki, Gunma, Kanagawa, Tochigi).