Custom design, production, installation and support after operation

The purpose is to greatly improve the reliability and productivity of the customer's manufacturing site.

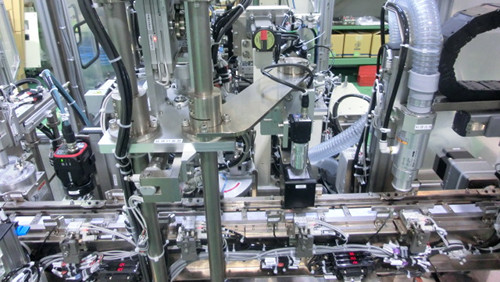

We offer design, manufacture, operation confirmation and support of customized automation system from standalone (cell production equipment etc.) to full automation production line.

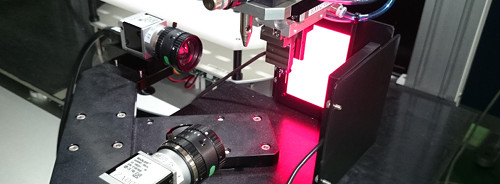

Robot - Image processing

Image processing

We design and manufacture from supply system to lighting, lens selection, image processing according to customer's specifications.

By harmonizing robot technology and image technology in addition to FA automation technology based on many years of experience, we are able to realize a wide range of products including board mounting of irregular parts, image inspection of parts /

We realize diverse automation.

Compatibility

Supports many parts supply forms

It corresponds to most supplies such as pallets, taping, sticks, parts feeders.

Flexibility

Automatic replacement of robot hands, change of posture of workpiece, automatic width change etc of conveyor, etc., flexibly respond to changes in workpiece shape, size and board size.

Versatility

In the board mounting and assembling apparatus for odd-shaped parts, the advantages of the compatibility and flexibility described above are taken advantage of and versatility is given to each robot frame, so even if it is necessary to change the production line due to specification change or the like, The addition of the number of units, change of accessories such as chuck, etc. can utilize the main body of the device as it is.

Assembly - Inspection system

Robot Integration

Designed and manufactured equipment that realizes flexible and efficient production by multi-step work such as transportation, assembly, parts supply, etc., with 6-axis robot consisting of one or more robots.

Assembly facility

Custom designed and manufactured various processes and mechanisms required for assembly, such as insertion, crimping, screw tightening, press-fitting, lamination, cutting, bonding, etc. according to the product.

We will solve problems on the site, such as parts that we have assembled manually, we can not assemble with manual hands, we want to assemble without quality variations.

Inspection

We will propose automation of inspection work making full use of image system and various sensors.

By incorporating these into equipment, a series of labor savings can be achieved from assembly to inspection process.

Handling

Design and manufacture of nail and gripping mechanism considering the size, weight, hardness, solid / liquid etc of the product to be produced.

We used various kinds of actuators such as 6 axis robot, 3 axis NC, cylinder etc

Design and manufacture of pick and place process.

Transport

Designed and manufactured conveying according to product and application

Pitch feed conveyance, conveyor conveyance, index conveyance, robot conveyance, etc.

Measurement and inspection

Designed and manufactured various inspection equipment according to the application

Design and manufacture inspection unit from electronic circuit to software

Image, laser, eddy current displacement, weight, current, voltage, temperature, pressure, flow rate etc.

Supply and storage device

Supply process of component, storage process of finished product

Design production according to various parts supply shapes and applications

Part feeder, palletizer, taping, separation shape etc.

Medical / Bio science / Laboratory automation System

Liquid medium preparation device

It is a device which automated the process of dispensing and mixing each of acid-fermented liquid medium.

We respond to customer's request, adjustment of various liquid media such as aerobic bacteria / blood culture / yeast bacteria.

Swab coater

Sampling work using swabs, such as DNA appraisal and pathogenic bacteria / microorganism identification, is diverse.

We will automate collection, addition and attachment work from a delicate foundation such as an agar medium, which could only be carried out by human feeling.

Production example

Production example

- Chemical container inspection / transport device

- Medical device assembling device

- Various inspection machines (scratches, burrs, shape, foreign matter, weight, electrical characteristics)

- Motor assembly device

- Printer parts assembling apparatus

- Electronic device assembling apparatus

- Automobile parts assembling / inspection equipment (sensor, board, relay, ABS etc.)

- Welding, laser marking equipment

- In addition, various assemblies, inspections, transportation, supply equipment

Production flow

- Review of new product launches, on-site troubles and so on.

We will examine the method for solving in consideration to the actual on-site thoroughly. - We consider and propose the idea of optimum equipment for customers considering quality assurance, takt time, maintainability, safety and cost performance.

- Technical team will perform concrete device configuration, hardware design, and software design.

- The design department, the assembly department, and the procurement department are involved as a crossing project, and we will manufacture the equipment.

- We will support you in total at the factory's startup at the customer's site and maintenance of the equipment.

Production request, estimate

If you are planning to introduce equipment such as automation, rationalization, custom made etc please contact us with the form below.

We will contact you shortly.

We will use the information you inquired about us only, we will not disclose or provide to third parties at all.